Metallurgical Analysis/Testing

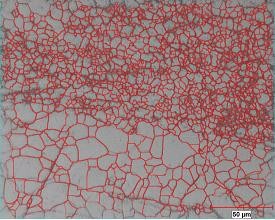

Metallurgical Analysis/Testing uses microscopy to provide important structure information about the properties of alloys. When metals are subjected to melting, cooling, and working processes, the grains and crystalline structures change. We study your microstructure and/or macrostructure to evaluate the effects on material properties.

We perform various types of microstructure and macrostructure examinations, corrosion analysis, grain sizing, and microhardness testing. We evaluate defects, determine structural features, identify alloys, evaluate the effects of heat treatments, and ensure materials conform to required specifications.

Metallurgical Analysis/Testing services include, but are not limited to:

- Particle Morphology and Composition Verification

- Coating Plating Thicknesses / Measurements

- Contaminant / Foreign Particle Analysis

- Mode of Failure Determination

- Fracture Surface Examination

- Optical / Electron Microscopy

- Baseline Chemical Analysis

- Material Defect Locating

- Microstructure Analysis

- Corrosion Studies

- Inclusion Analysis

- Heat Treatment

- Macro Exam

- Grain Size

- Ferrite