Specialized Testing

What is “Specialized Testing” – simply stated, we’ll take on projects that others don’t (or won’t). These projects require assessment, research, communication... and most importantly, are projects on which you need support. Below are two case studies Industrial Testing Laboratory Services specialists have encountered.

Case #1

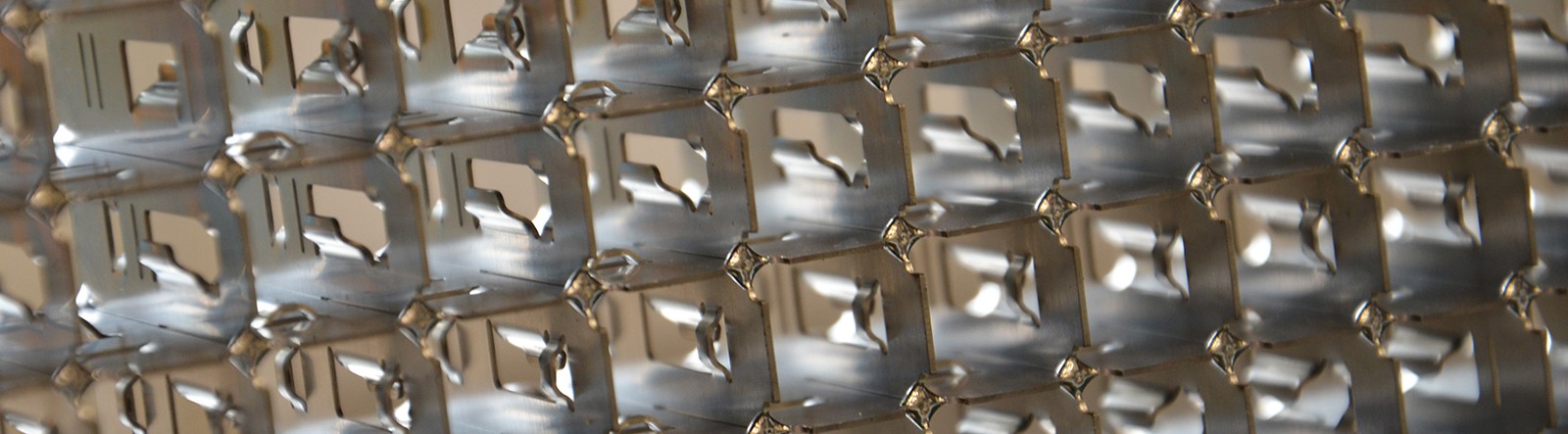

Refueling assemblies in a nuclear power plant have springs/straps that contain the fuel rods into finite assemblies. These items may have flaws created in the primary process, which surface during secondary processing. Because the material used supports extreme temperatures, conventional liquid penetrant (PT) inspection techniques are no productive in flaw finding. To solve this, we created a unique/proprietary PT process that was proven reliable and consistent in flaw detection.

Case #2

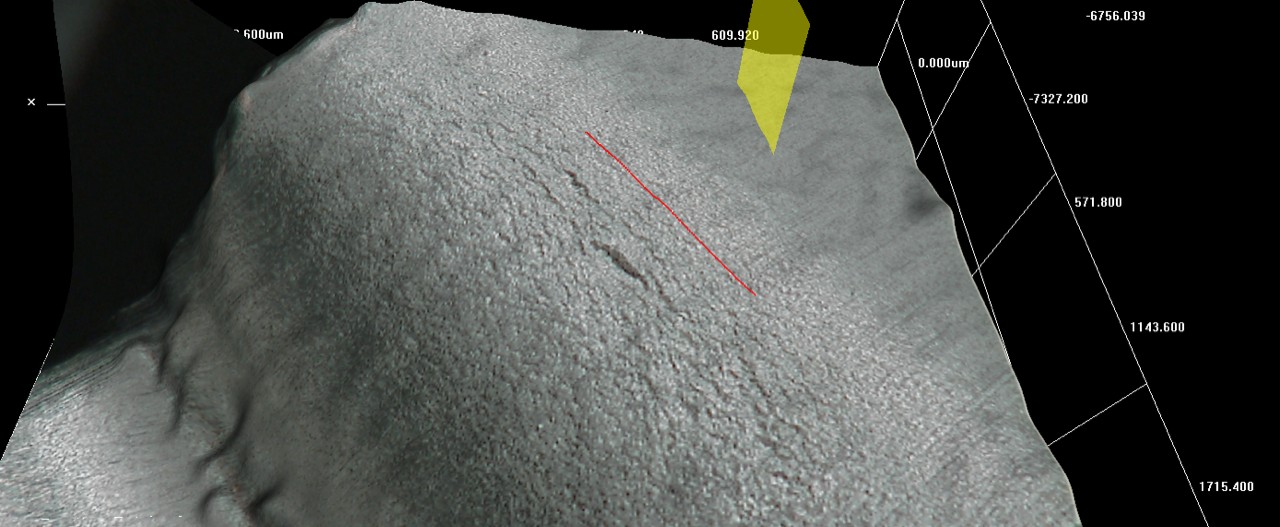

A customer needed to use unglazed ceramic insulators in a pump, to feed electrical conductors to its internals. A number of manufactured insulators were cracking upon initial installation. We were tasked to find material cracks in the unglazed ceramics. To do this, we created a proprietary PT process to find these flaws.